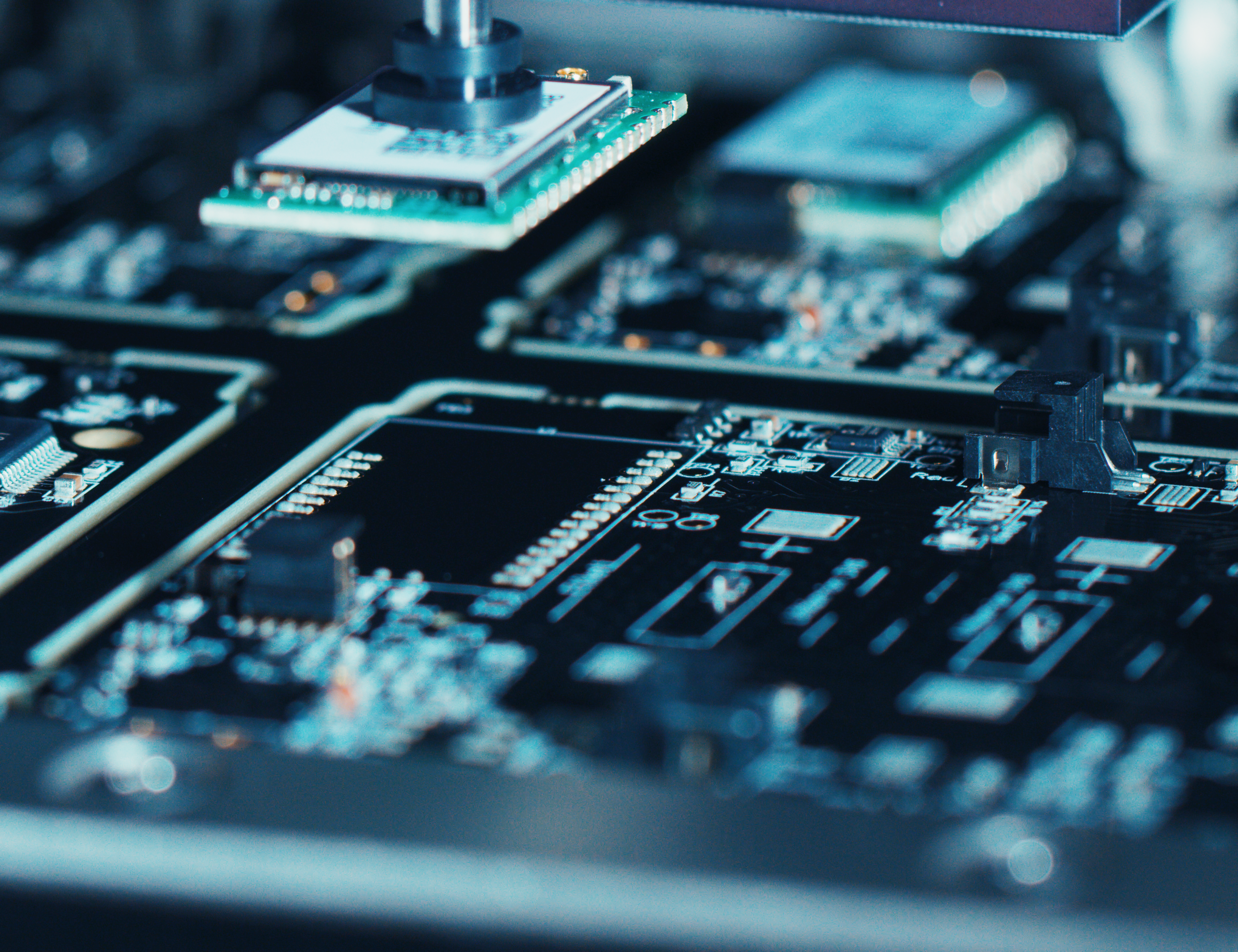

- Manufacturing

- Optimization

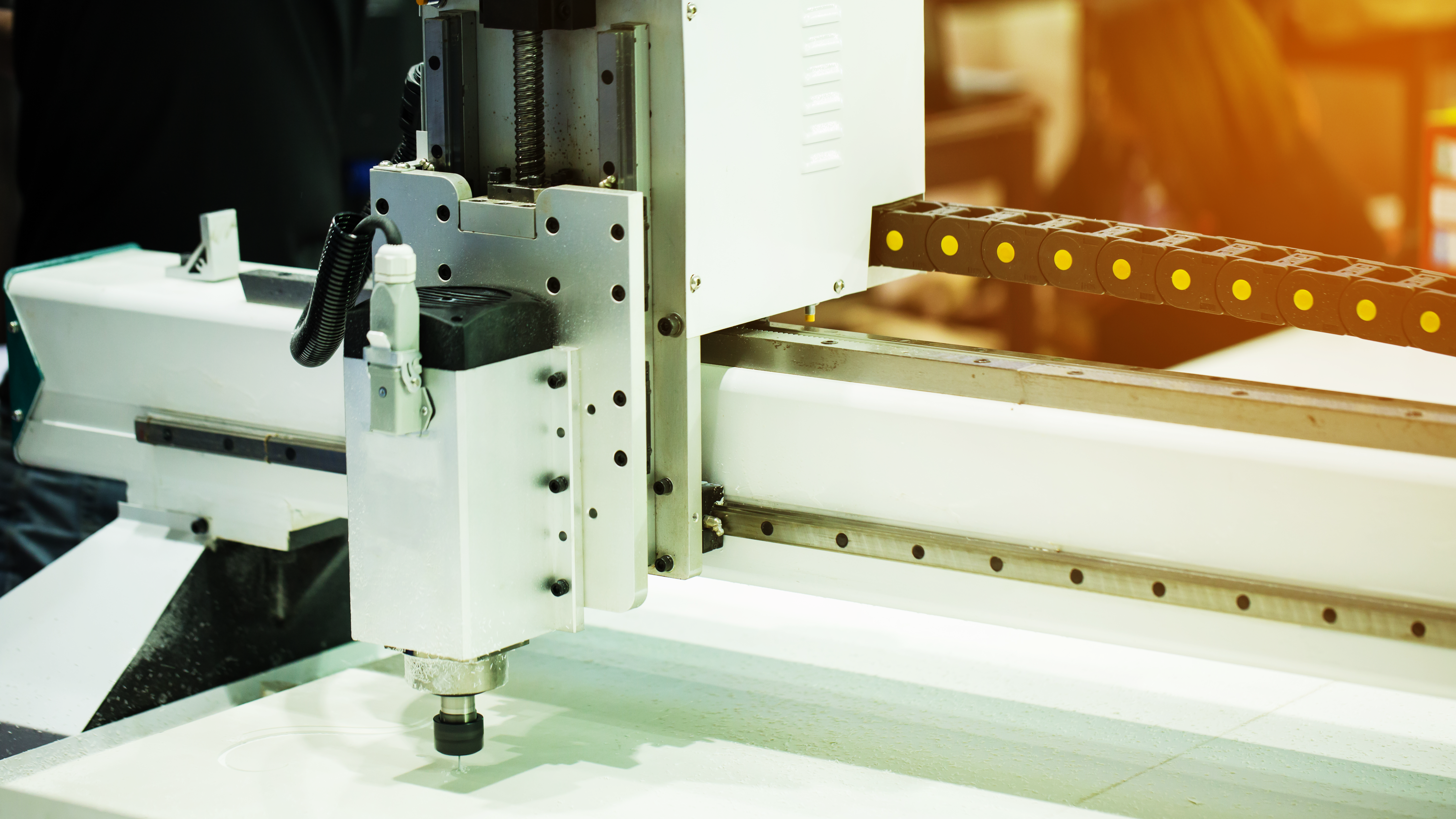

Parameter Tuning Automation: 52% Faster, 20% More Accurate

Enhance motion control accuracy with data-driven simulators and reinforcement learning for automated parameter tuning, minimizing the gap between commanded and actual values.

READ MORE